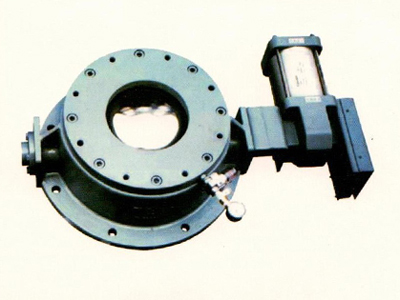

The dome valve spool is spherical, in the switching process, there is a gap about 2mm between the valve spool and rubber sealing ring, so that the valve spool and rubber sealing ring can move in a non-contact way to reduce wear.

The pneumatic actuator of the dome valve is a fully sealed rotary cylinder, which directly drives the rotation of the dome valve, effectively preventing dust from entering it and causing wear, leakage and so on. When the dome valve is in the closed state, the rubber sealing ring is inflated and tightly pressed on the spherical dome valve spool, thus forming a very reliable sealing ring belt to prevent the flow of materials in the pipeline.

Depends on different using conditions the material of dome valve spool are different, and the surfaces adopt different hardening treatments. Using the smooth and hard surface, the rubber seal ring can be well connected to ensure the reliability of sealing. The rubber seal ring is made of special material which is high temperature resistance, corrosion resistance, wears resistance, aging resistance and has long service life. When the valve opens, the material flows free.

This valve is suitable for the following medium: gases, liquids, semi-fluids and powders.

1. Application and characteristics

Dome valve is a new type valve that can achieve quick open and close. It uses international advanced pneumatic seal structure, so the spool won’t touch the inflatable ring while valve opening or closing. The seal ring is made of specially formulated rubber, and it can be widely used in the sealing of powdery material. Dome valve is the key part in pneumatic material conveying system, and is widely used in electric power, metallurgy, chemical industry, food, pharmacy and other fields.

Valve spool won’t touch sealing ring during movement, which will achieve small resistance and long service life.

Use inflatable seal ring with reliable sealing.

Pneumatic actuator is fully enclosed driven by Straight cylinder or fan cylinder, with high output torque and reliable performance, is able to work under bad working conditions.

2. Design Features

| Grinding materials: Slurry, loose powder, particles, clumps or gaseous dust will wear out the seal ring, resulting in an ineffective seal. Inflatable sealing ring provides continuous wear compensation for this. Pressure difference: pressure difference will accelerate the abrasion of traditional hard sealing valves. But the inflatable seal ring will provide continuous compensation for this abrasion. High temperature: Thermal expansion will hinder the continuous action of the dome valve. The inflatable sealing ring is able to provide wear compensation at temperatures ranging from 0℃ to 350℃. Special structured dome valve is adequate above this temperature range. Closing and sealing: The movement of the rotating dome spool in the body rotates the solid material column so that the fully filled dome valve can be closed and sealed through the filled material. Wear/Temperature/Pressure: Traditional hard sealed alves Reliability: The dome valve is designed to be strong to be adequate for the works that other valves cannot undertake. These dome valves only need to be tested after one million times of standard operation. |

3. Matters and Attentions

The inflation pressure of rubber sealing ring shall be 0.30~0.60MPa, and 0.15MPa higher than the conveying pressure. The working pressure of cylinder is 0.45~0.65MPa, using clean, dry and oil free compressed air. |

|

4. Key points for installation and use

1) Read the specification carefully before installations, and check the model number, nominal diameter and technical parameters.

2) Flange welding is not allowed after the valve is installed, in case the sealing ring is damaged. The space reserved for valve installation shall be suitable and spacers shall be set on both sides of the flange.

3) Both pipe centers and valve centers shall be coaxial, flange surface shall be flat and without large tilt.Fasten the bolts symmetrically to ensure the tight and proper functioning of valves.

4) The valves have been adjusted and passed the dynamic test, and air lines are unblocked.

5. Wear Parts

The main wear parts are mostly sealing ring and valve spools.

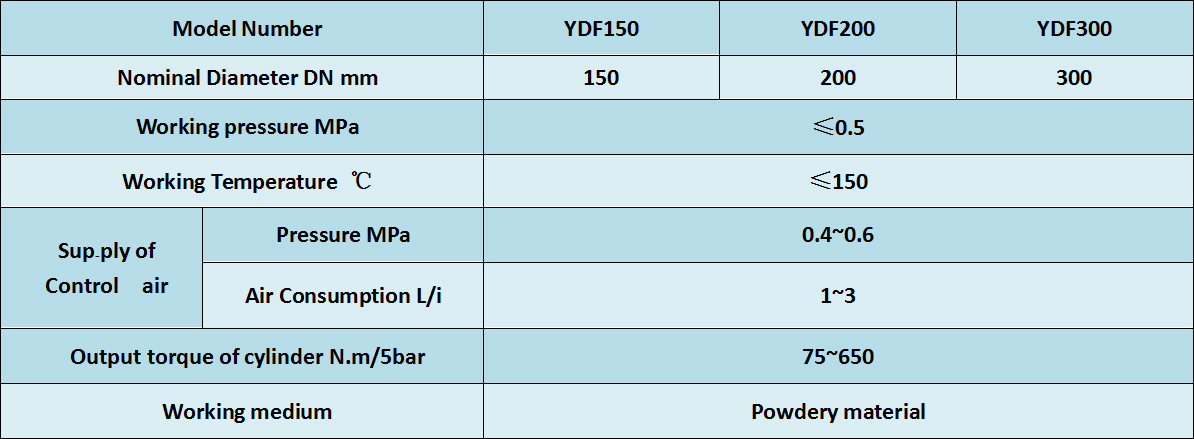

6. Main Technical Parameters