1. Application

· By introducing RSZ type rotating feeding valve produced by America VOLK Valve Company, it applies to solid material handling system and it’s the dedicated device for high and low temperature discharging, unloading, packing, mixing, measuring and quantitative input.

Core parts, shell and impeller are made out of America imported special steel, they have high abrasion resistance, high corrosion resistance and high temperature resistance. They are widely used in power, chemical, food, medicine, coal and other industries.

2. Performance

1) The allowed particle size of material is 0~15mm,

2) The gap between rotator and shell can be adjusted according to characteristics of material and temperature (cannot be adjusted without knowing the situation of valve),the adjustment of gap won’t affect the sealing of rotating feeding machine.

3) The cover on the both sides of impeller is sealed well, which makes less maintenance.

4) The external bearing that supports the impeller shaft will not be abraded by material, which makes the impeller shaft not easy to get stuck.

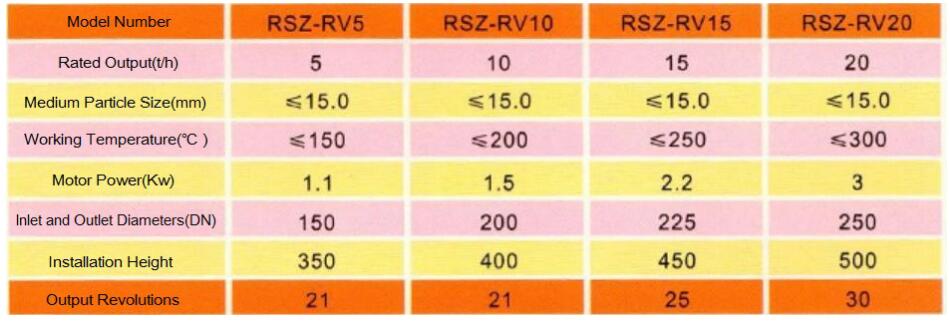

3. Main technical parameters

4. Operation description

1) Make sure the machine is in normal operation speed before feeding materials.

2) Operation : Continuously

3) Normal material particle size: 0~15mm

4) Working temperature: not exceeding 550 ℃.

5. Control function

The following functions can be implemented according to customer requirements

1) Local and remote control functions enable on-site, remote start-stop, PLC, DCS access systems, achieve local monitoring power and equipment operation, stall alarms and other conditions.

2) Speed control function: control the indoor DCS output control command to control the rotation speed of the rotary feed valve, and feed the speed signal back to DCS.

3) The stuck alarm signal, the feed valve outputs the passive switch contact signal to the DCS, and the DCS output switch contact signal to the local control box of factory to realize the motor reversal, that is, the control box has the reverse operation function.