The manufacturing base of United Burgmann in China has manufacturing lines for various types of mist eliminators and high-efficiency scientific management & quality systems. It has obtained certification from American Society of Mechanical Engineers (ASME) which ensures the best products, technologies and service.

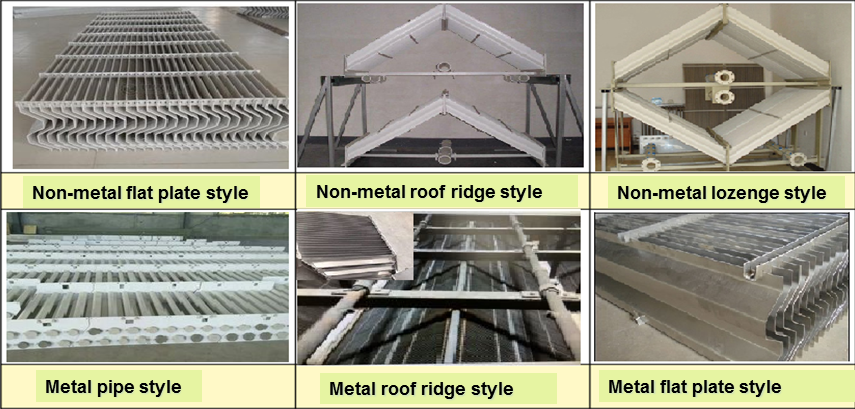

Main mist eliminator products:

There is a variety of mist eliminators, including pipe style, flat plate style, roof ridge style and combination of different styles. Mist eliminator impellers can be made of reinforced polypropylene(PP), inflaming retarding PP, stainless steel, etc.

Metal mist eliminators of United Burgmann adopt alloy impellerswith high-strength, corrosion resistance, large bearing capacity, long lifespan and difficulty in fouling.The alloy’santi-corrosion for Cl- is more than 50000ppm.

● Modularization design is convenient for installation and maintenance;

● Multi-stage layout can meet various requirements from different clients;● Normally the mist eliminators from United Burgmann consist of two or three stages. of Stage 2 and stage 3 have the same waveformheight as stage 1, but their impellers are attached with hooks and less space;

● As primary separation device, impellers for 1ststage mist eliminator are 30mm away from each other and undertake 70%~90% mist elimination task;

● As secondary separation device, 2nd stage mist eliminator will eliminate mist missed by 1st stage mist eliminator. Space between 2nd stage mist eliminator impellers is ≤30mm. After elimination of these two stages, liquid droplets density in flue gas can achieve an amount ≤75mg/Nm3;

● When a client demands extremely low liquid droplets density in flue gas after FGD system, then a 3rd stage mist eliminator might be added with ≤25mm space between its impellers. After elimination of these threestages, liquid droplets density in flue gas can achieve an amount ≤20mg/Nm3.