Technical overview

Side entering agitators are important equipment affiliated to devices such as large storage tanks/vessels and flue gas desulphurization absorbers.

Devices like flue gas desulphurization absorbers adopt ventilating agitation and have high demands during agitation and mixing process as below:

1. smashing air bubbles in order to increase contact interface between air and liquid, so that mass transfer rate between air and liquid can be raised;

2. relatively large slurry flow circulating load to keep solid content in slurry in suspension state.

etc.

Thus, agitators are required to possess strong shearing force and meanwhile significant characteristic of fluid circulation.

Functions of a side entering agitator are to prevent slurry in devices like FGD absorbers from precipitation & incrustation, to ensure complete oxidation of slurry in absorbers, and to keep slurry in continuous flowage status.

Normally, there are two types of side entering agitators for users to select, belt drive side entry agitators and spiral conic gear side-entry agitators.

Technical advantages

(1) Impellers of side entering agitators are of pitched turbine type. They have certain shearing force and meanwhile generate strong axial circulation

(2) flow, thus better air-liquid dispersion can be achieved, air containing rate and mass transfer coefficient are large, and power required for agitating is low. Tilt of impeller vanes increases the air coverage by impeller vanes, and flooding point & rotation velocity are relatively low.

(2) Mechanical seal of a side entering agitator is of cartridge type. This cartridge type changes sealing surface of the rotating shaft from axial direction into radial direction, and achieve sealing function through mutual jointing of rotor ring end face and stator ring end face and relative movements. Low leakage possibility of mechanical seal ensures reliable air tightness, low power consumption and long life span. No frequent maintenance or repair work is required.

(3) It’s not necessary to pump out slurry in a flue gas desulphurization absorber when repair work or sealing ring change work is required for a side entering agitator. A simple series of actions will satisfy, including pulling out the agitating shaft for a small distance, making sure that the end cap enters into the seal receptacle, rotating the shaft so the end cap and seal receptacle can tightly tie to prevent slurry in absorber from leaking.

(4) Side entering agitators are applicable to sliding & precipitation prevention occasions and various fluid mixing medium of 0∽0.5MPa working pressure and -10∽1200C work temperature.

(5) Spiral conic gear side-entry agitators are applicable to mixing of low viscosity materials, large storage tanks/vessels, and wet flue gas desulphurization absorbers & slurry sumps.

(6) Belt drive side entry agitators are driven by belts which shrinks the center –to-center distance and compacts the physical form, achieving high driving efficiency, precise driving, stability, low noise, zero slippage and energy saving.

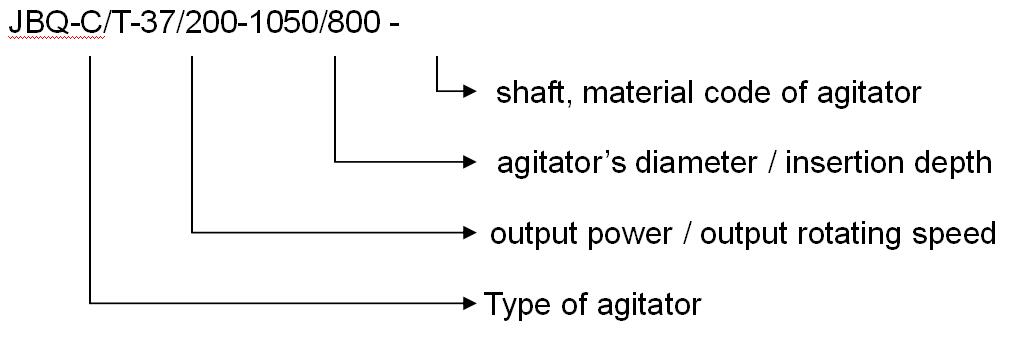

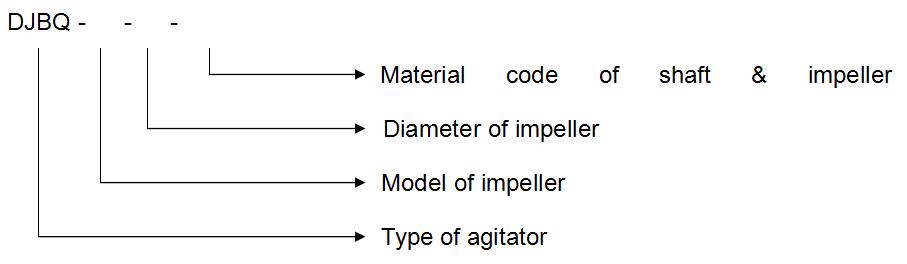

Type & symbol definition and demonstration

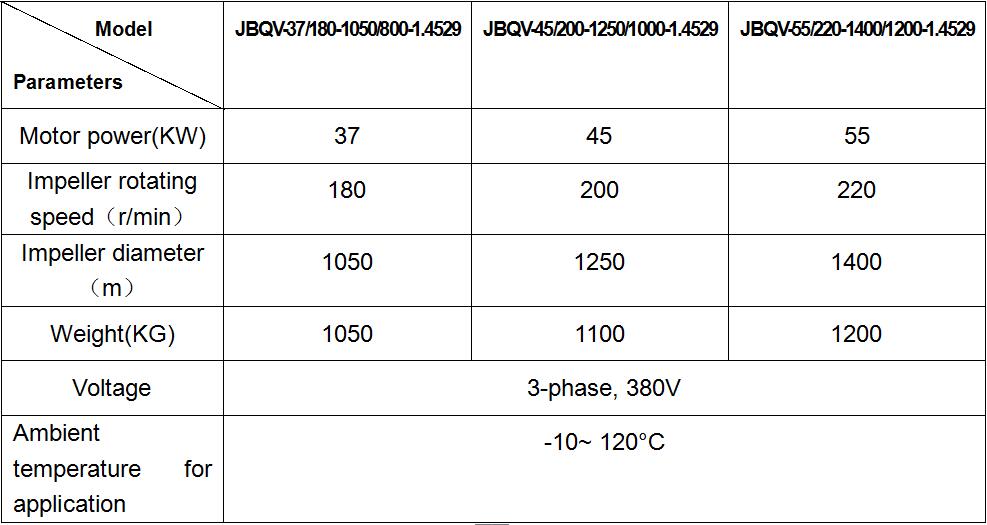

Basic parameters of a spiral conic gear side-entry agitator

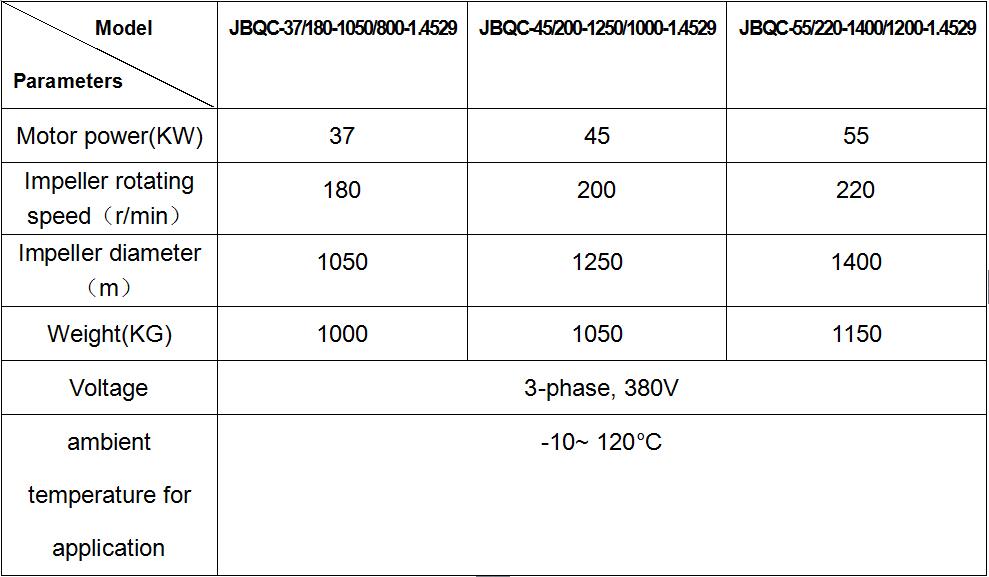

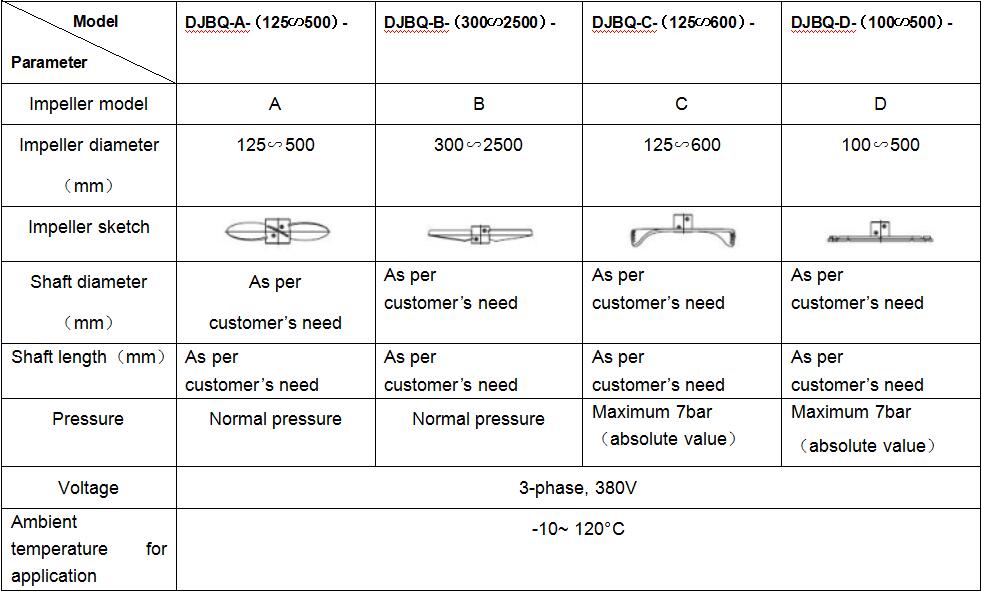

Basic parameters of a belt drive side entry agitator

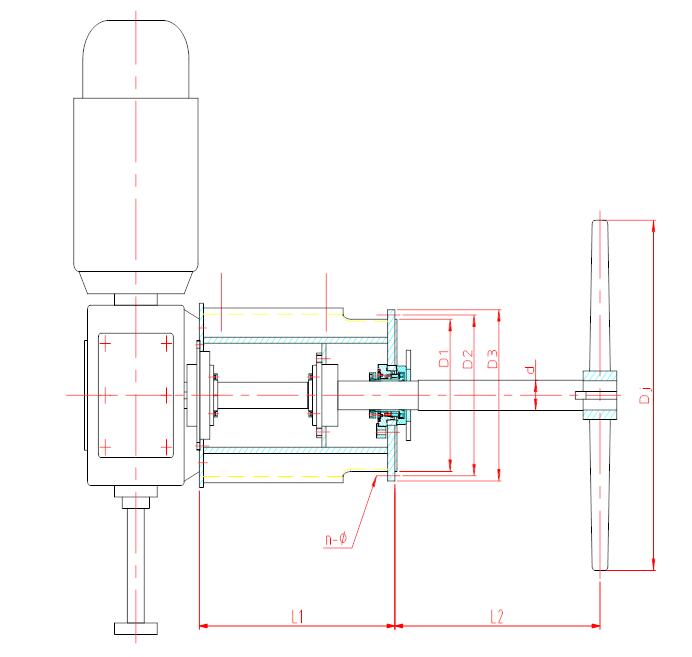

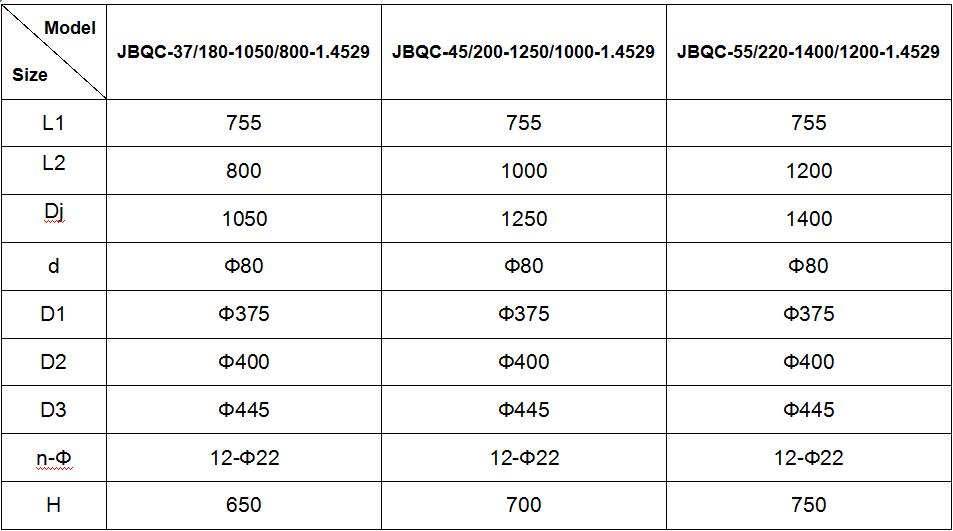

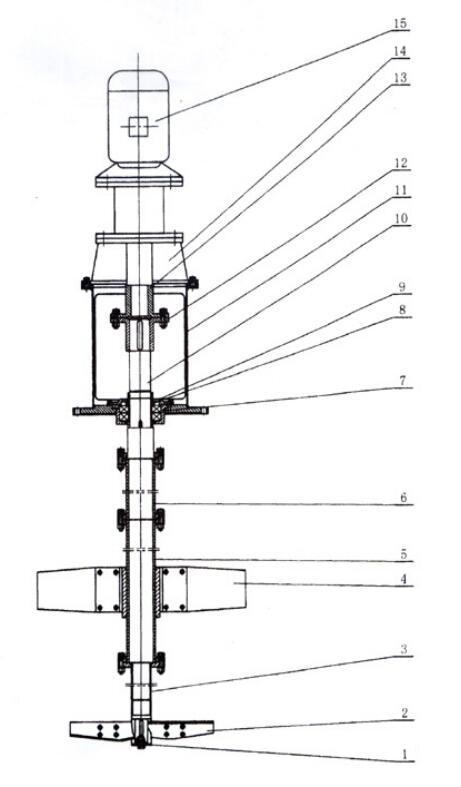

Basic sizes and configuration of a spiral conic gear side-entry agitator

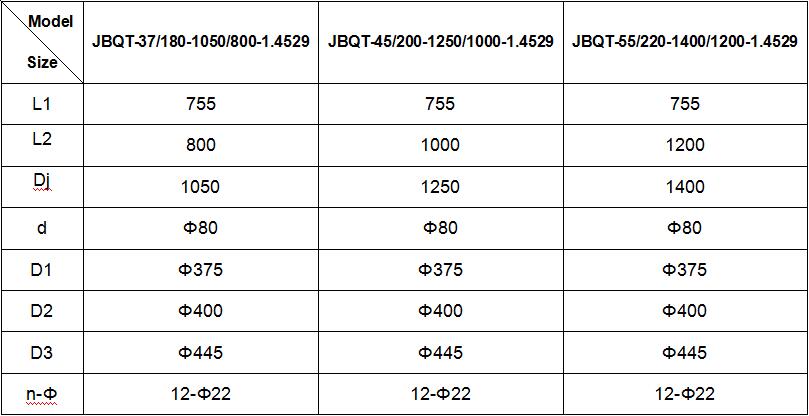

Basic sizes and configuration of a belt drive side entry agitator

Top Entering Agitator

Technical overview

The series of top entering agitators are designed by our specialized fluid flow engineers. Tremendous tests prove their practicability and that maximum flow rate per unit power can be generated.

Top entering agitators are applicable to diameter variable slurry sumps

During equipment development, computer analyzes the same equipment program, design of wings, shape of impeller vane, rate of curving and impeller’s gradient of slope have to be harmonious, flow rate must be maximized and daggling must be minimized to achieve maximum efficiency.

There are four impellers with low gradient of slope & degree of curvature on a top entering agitator. The impeller is conic, the low tilted vane on top of impeller owns maximum speed, while the high tilted vane approaching to axle center owns relatively low speed. In relatively slow rotation speed, mixing efficiency of vane approaching to axle center can be raised by increasing curvature from top of impeller to axle center.

Technical characteristics

Low power for shaft of agitator reduces power consumption cost;

Simplified installation and non-requirement of mechanical sealing;

Water flushing on mechanical sealing position is not required;

Divided impeller and wheel hub, integrated design or spiral design;

Polishing, special alloy material or rubber lining material.

Materials available for impellers include SS316, SS304, rubber lined carbon steel, Hastelloy alloy, A-20, titanium alloy, bi-directional alloy C108, super Austenitic alloy, etc.

Technical advantages

Through professional software analysis, impellers of top entering agitators possesses better mixing capacity than others.

Impellers’ efficiency of the series of top entering agitators is better than that of flat impellers. Impellers of top entering agitators by particular manufacturing procedures have better efficiency and higher strength, and can avoid bending by fluid thrust force.

Under the condition of the same power, impellers of top entering agitators can be designed with low tilt vane and larger diameter. Due to the fact that fluid thrust force is symmetrically acts on impeller’s diameter, bigger top entering agitators are steadier in operation and without burden of driving mechanism. Thus, top entering agitators own higher rotation speed ratio between impeller diameter and vessel diameter, and that’s the top reason of agitator selection.

Considering even distribution of fluid thrust force, top entering agitators with four impellers have better stability than those with three impellers.

There are three types in top entering agitators, integrated cast agitators, welded agitators and distributed outline agitators. Rigid vanes on impellers are welded or spirally connected to impellers, the simplified curving vanes can satisfy low torque application, but they possess high torque and curvature, and can maximally reduce the load of agitator’s driving mechanism.

Spiral connection adopted eases its installation and meanwhile decreases operation & maintenance cost.

Type & symbol definition and demonstration

Basic parameters of top entering agitators

Structural style of top entering agitators

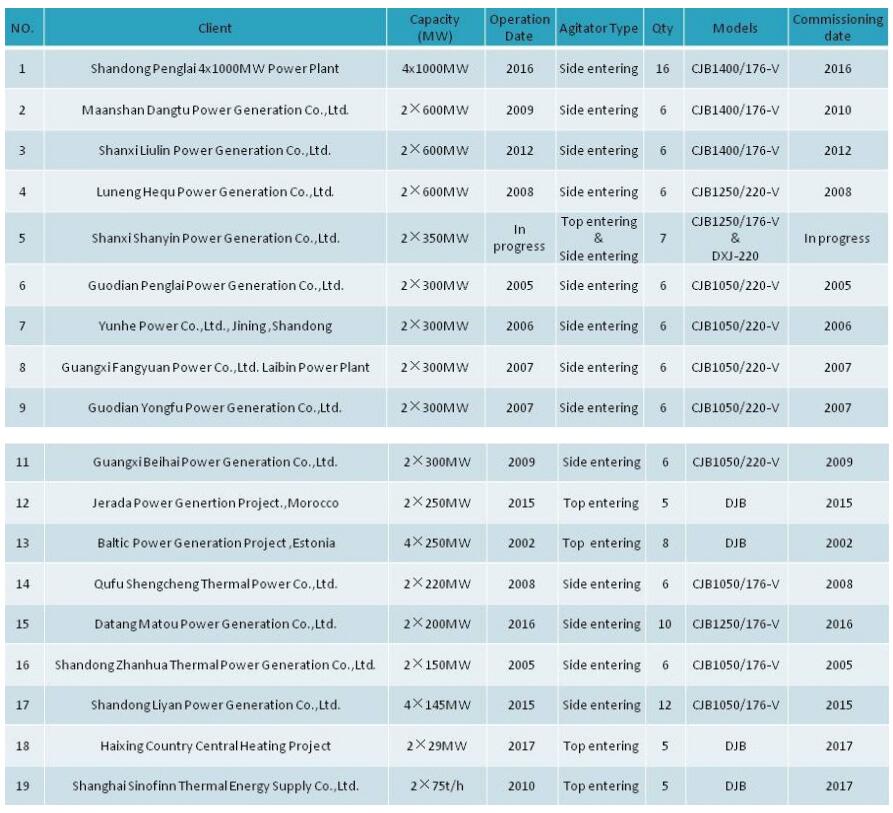

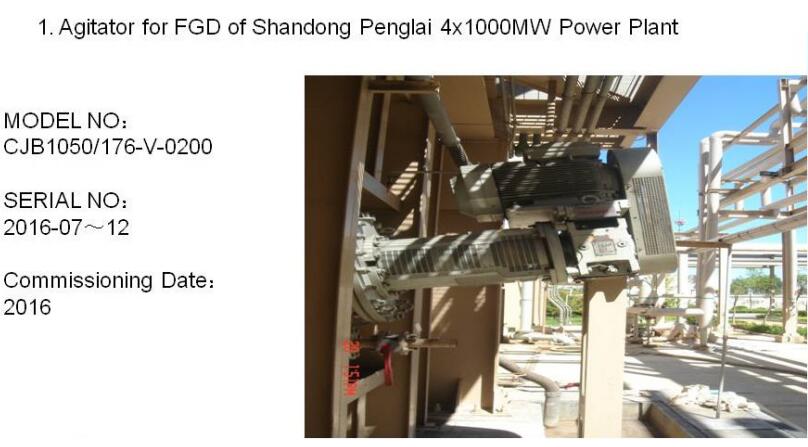

Achievements & Reference

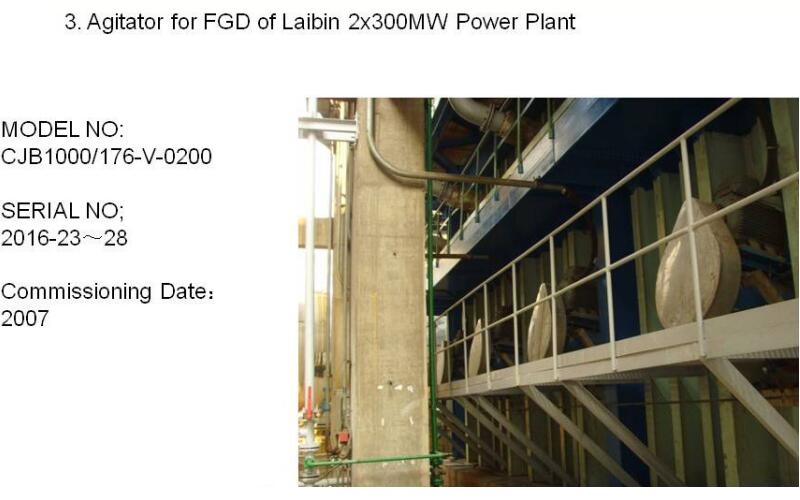

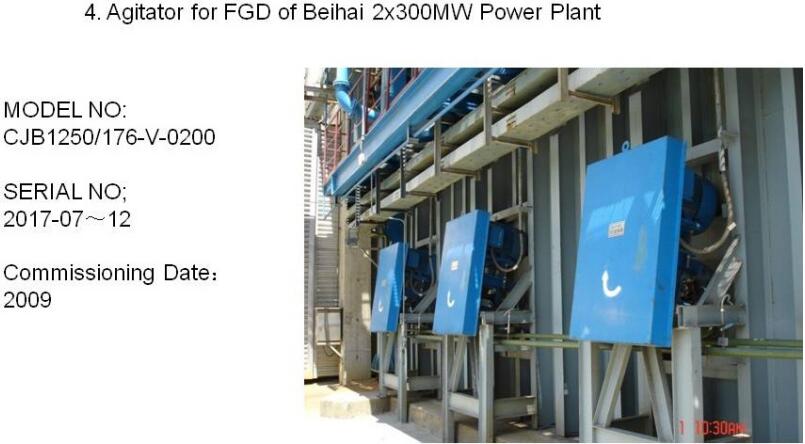

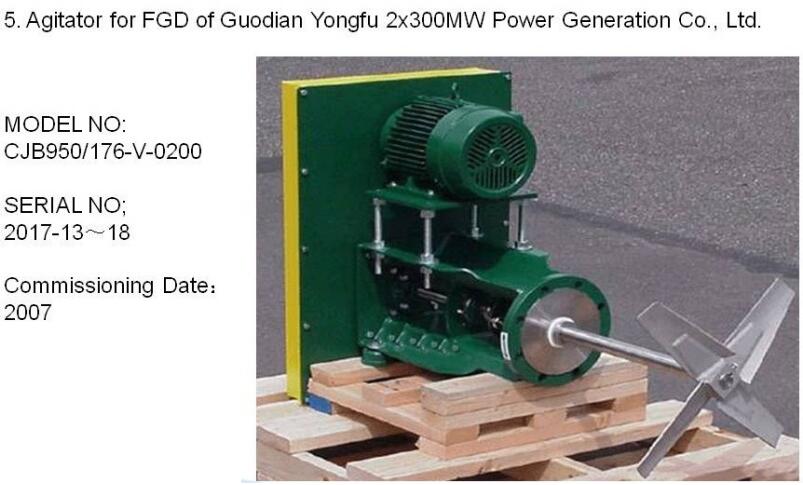

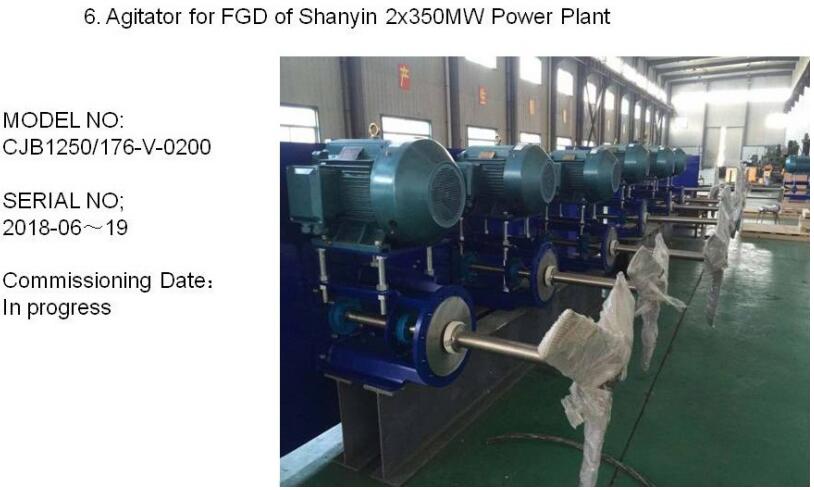

Reference list